How do you save countless hours trying to explain a complex process to potential suppliers, stakeholders and operators?

DITLO for Transport for London

TfL typically outsources fleet-wide rolling-stock refurbishments to suppliers such as Bombardier, Alstom or Wabtec. However, on this occasion, they wished to change the status quo and develop their own in-house capability.

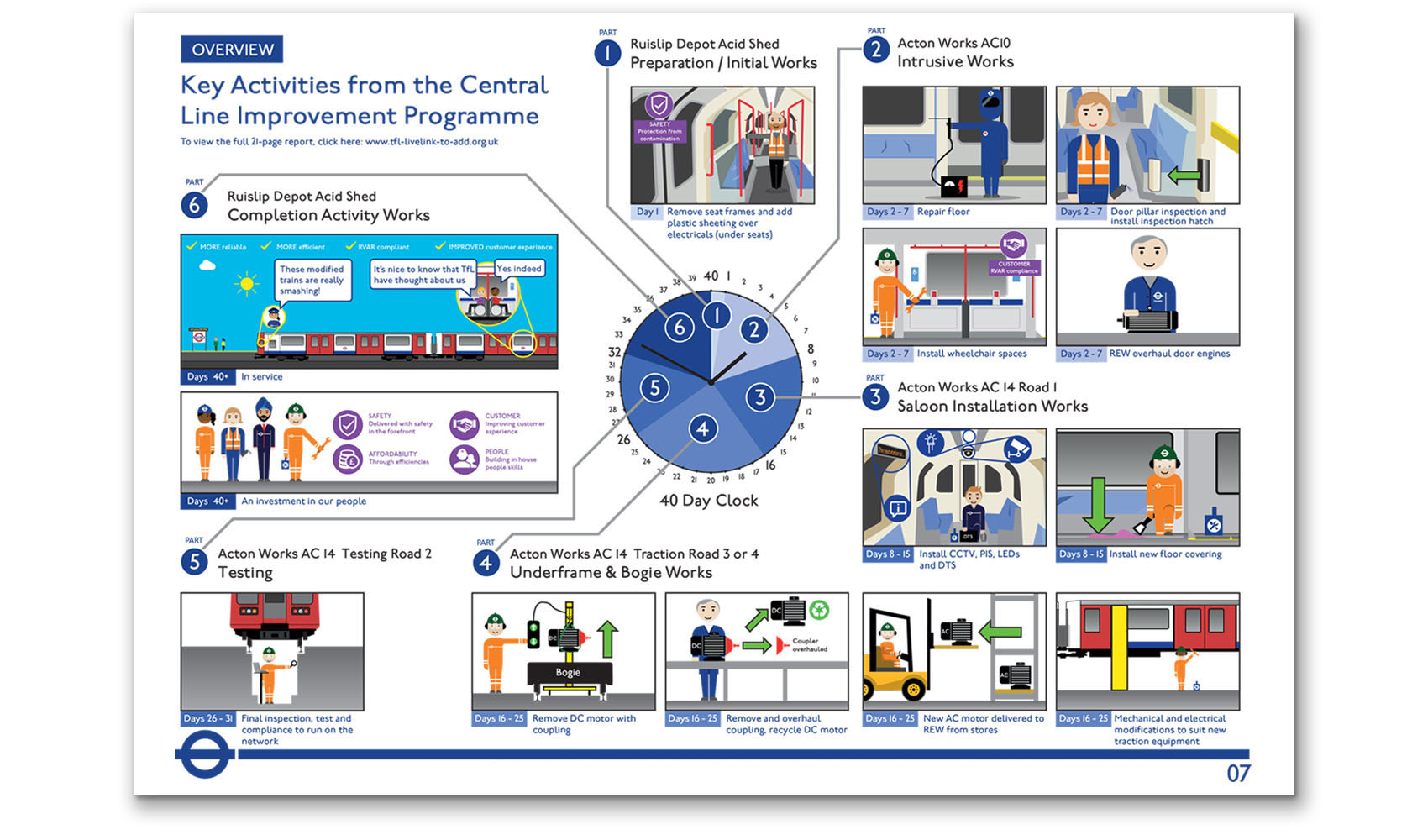

For the fifth time in as many years, WillB worked with TfL to create an illustrated Day In The Life Of (iDITLO) storyboard. In this instance, we helped to explain, step-by-step, London Underground’s vision of how they would refurbish each of the 85 trains in 40 days.

The iDITLO broke down the process into a granular level, including a list of the staff required, the train movements, as well as each activity entailed.

The process of creating the iDITLO, including initial discussions, two workshops, and original artwork, was delivered within a 6-week period.

Photograph of the live sketches done during one of the workshops (at 172 BPR)

p10 of 21. Part 0: showing the train being shunted into the Acid Shed at Ruislip Depot

“An invaluable piece of work, which has saved countless hours trying to explain a complex process to potential suppliers, stakeholders & operators.“

Owen Holmes, Project Manager, Fleet – Renewals and Enhancements, London Underground

p8 of 21. Introduction of all roles involved in the work.

p4 of 21. Overview of the tube train being improved.

p6 of 21. Forty-day clock showing the refurbishment and movements of one train.